Stainless steel is a solid and durable material, which is very suitable for indoor and outdoor structure and design. Using colored stainless steel plates can integrate color elements into your personalized design. Colored Stainless Steel Sheets has been applied more and more widely in recent years due to its unique characteristics.

Overview

Colored stainless steel sheets have been applied more and more widely in recent years due to its unique characteristics. Nowadays, colored stainless steel products are widely used in buildings abroad, and colored stainless steel plates have become popular. China color stainless steel has both metallic luster and intensity and has a colorful and everlasting color. KLS produces different types of colorful stainless steel plates. These colored sheet metals are manufactured according to the highest standards, and high-quality materials are used.

Austenite is the most suitable coloring material for colored stainless steel, and a satisfactory color table can be obtained. Ferritic stainless steel will corrode in the coloring liquid, and the resulting color will not be bright. Due to poor corrosion resistance, low chromium high carbon martensitic stainless steel can only get a gray or black surface

Commonly used austenitic stainless steel grades are 201, 202, 304, 304L, 310S, 309S, 316, 316L, 321, and so on. Colored sheet metal provides attractive decorations for general and harsh environments. PVD (Physical Vapor Deposition) surface treatment is very durable, which is actually harder than stainless steel surface itself.

The stainless steel coloring process of PVD (Physical Vapor Deposition) is the hardest and lasting method. Place the product in the vacuum chamber, the proprietary mixture of heating metals and compounds, which evaporates them, and pulls them over the vacuum chamber with magnets, forming a uniform and super tough coating on the coated product.

PVD coated stainless steel sheet is very suitable for indoor and outdoor, because it can maintain color for many years, which is very suitable for secondary coating of stainless steel. Chemicals and cleaners usually do not affect the decorative surface.

Features

New material coloured stainless steel sheets are chemically treated on the surface of stainless steel. The main products include colored stainless steel plate and stainless steel decorative board. Color stainless steel is processed by stainless steel plates for PVD technology to make it a stainless steel decorative board with a variety of colors. Its color is light gold, yellow, golden, white blue, dark artillery, brown, young, golden, bronze, pink, champagne, and stainless steel decorative boards of various other colors.

Colored stainless steel decorative boards have the advantages of strong corrosion resistance and high mechanical properties; color surfaces do not fade, and color changes with the angle of color tone. In addition, the color surface layer of the color stainless steel decorative board is 200″, and the salt-resistant corrosion performance is better.

Colored Stainless Steel Sheet can be molded, stretched and bent.

The stainless steel sheet metal has the characteristics of strong corrosion resistance, high mechanical properties, long color color surface, color change with different light angles, color stainless steel plate and so on.

Non-ferrous stainless steel has no change in color after being exposed to industrial atmosphere for 6 years, exposed to marine climate for 1.5 years, immersed in boiling water for 28 days or heated to about 300°C.

If you are looking for wholesale colored stainless steel sheets from trusted manufacturer, welcome to contact us for detailed information!

Specifications

| Product Name: | Colored Stainless Steel Sheet |

| Grades: | 201, 202, 304, 304L, 316, 316L, 321, 347H, 409, 409L etc. |

| Standard: | ASTM, AISI, SUS, JIS, EN, DIN, BS, GB,etc |

| Certifications: | ISO, SGS, BV, CE or as required For India, Russia, Europe, America, Middle East, Saudi Arabia, Qatar, etc. |

| Thickness: | 0.3mm-3.0mm |

| Width: | 1000 - 2000mm or Customizable |

| Length: | 2000 - 6000mm or Customizable |

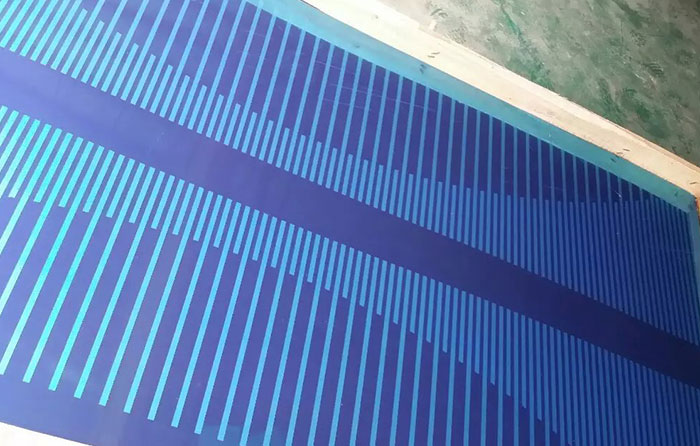

| Surface: | Gold mirror, Sapphire mirror, Rose mirror, black mirror,bronze mirror;Gold brushed, Sapphire brushed, Rose brushed,black brushed etc. |

| Delivery time: | Normally 20 days or negotiable |

| Package: | Standard Seaworthy Wooden Pallets/Boxes or as per clients' requirements |

| Payment terms: | T/T, 30% deposit should be paid in advance, the balance is payable at sight of the copy of B/L. |

| Applications: | Architectural decoration, luxury doors, elevators decorating, metal tank shell, ship building, decorated inside the train, as well as outdoor works, advertising nameplate, the ceiling and cabinets, aisle panels, screen, the tunnel project, hotels, guest houses, entertainment place,kitchen equipment, light industrial and others. |

Uses

The surface of colored stainless steel sheet products is stronger than ordinary stainless steel. It can withstand more than 10 years of salt and fog corrosion and ultraviolet rays of more than 30 years.

As one of the professional colored stainless steel sheet suppliers, KLS provides colorful stainless steel plates for the architecture and design industry to create unique appearance and interior for various residential and commercial places.

The color surface has the advantages of colorful, soft, strong, and high smoothness. Colored stainless steel plates are widely used in elevators, hardware home appliances, kitchen appliances, cabinets, building decoration, advertising signs, daily necessities and other fields, including:

1. Used for building exterior wall decoration and interior decoration.

2. Stainless steel colour sheet combined with printing, using etching, grinding, dot matrix method to produce indelible three-dimensional reliefs, murals, screens.

3. Use colored stainless steel to make household appliances, cooking utensils, kitchen equipment and bathroom utensils.

4. The heat absorption rate of the black stainless steel plate can be as high as 91% to 93%.

The mirror panel, also known as 8K panel, is polished by polishing equipment on the surface of stainless steel with abrasive liquid to make the surface as bright as a mirror, and then electroplated and colored

The surface of the drawing board has a matte silk texture. A closer look reveals that there is a trace on it, but I can't feel it. It is more wear-resistant than ordinary bright stainless steel and looks more advanced.

There are many kinds of patterns on the drawing board, including hairy silk (HL), snow sand (NO4), lines (random), crosshairs, etc. Upon request, all lines are processed by an oil polishing machine, then electroplated and colored.

The zirconium beads used in the sandblasting board are processed on the surface of the stainless steel plate by mechanical equipment, so that the surface of the sandblasting board presents a fine bead sand surface, forming a unique decorative effect. Then electroplating and coloring.

According to process requirements, multiple processes such as polishing hairline, pvd coating, etching, sandblasting, etc. are combined on the same board, and then electroplated and colored

From a distance, the pattern of the chaotic pattern disc is composed of a circle of sand grains, and the irregular chaotic pattern nearby is irregularly oscillated and polished by the grinding head, and then electroplated and colored.

Etching board is a kind of deep processing after mirror panel, drawing board and sandblasting board are the bottom plate, and various patterns are etched on the surface by chemical method. The etching plate is processed by multiple complicated processes such as mixed pattern, wire drawing, gold inlay, titanium gold, etc., to achieve the effect of alternating light and dark patterns and gorgeous colors.