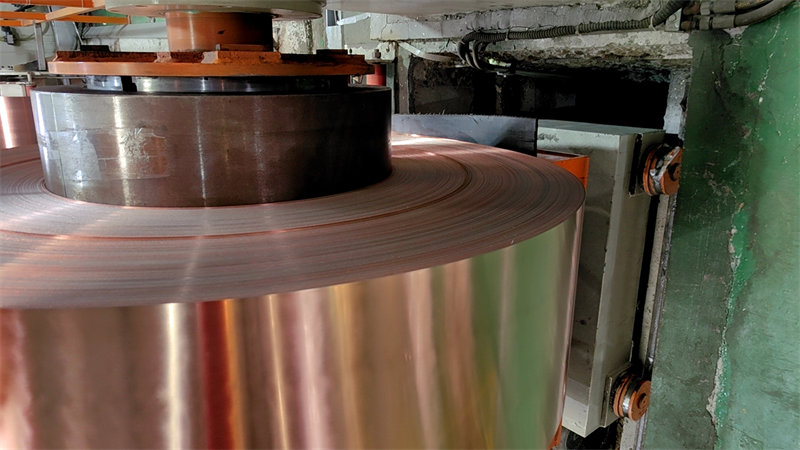

Copper clad steel coil is a type of metal coil that consists of a steel core coated with a layer of copper on both sides. The manufacturing process involves bonding the copper layer to the steel core using a specialized rolling process.

Overview

Copper clad steel coil is a type of metal coil that consists of a steel core coated with a layer of copper on both sides. The manufacturing process involves bonding the copper layer to the steel core using a specialized rolling process. This process ensures that the copper layer is evenly distributed on the steel core and has excellent adhesion.

Features

Copper sheet coil is a metal clad consists of three layers of high-quality materials, meticulously crafted to provide exceptional performance and durability. The first and third layers are made of C1020R copper, renowned for its excellent electrical conductivity, corrosion resistance, and ductility. The second layer is constructed using stainless steel 316L, chosen for its superior strength, corrosion resistance, and suitability for demanding environments.

With a ball coil diameter of Φ 500, our copper sheet coils offer a versatile solution for various applications. Its carefully designed layers ensure optimal performance, making it an ideal choice for industries such as electrical, electronics, construction, automotive, and more.

Features of Copper Sheet Coils:

1. Excellent Electrical Conductivity: Copper is renowned for its exceptional electrical conductivity, making copper clad steel coil an ideal choice for applications that require efficient electrical transmission.

2. Superior Thermal Conductivity: Copper has excellent thermal conductivity, enabling effective heat transfer and dissipation in applications where thermal management is crucial.

3. Corrosion Resistance: Copper exhibits high resistance to corrosion, making copper coated steel suitable for applications in harsh environments or where exposure to moisture and corrosive elements is common.

4. Ductility and Malleability: Copper is highly ductile and malleable, allowing copper clad stainless steel to be easily formed into various shapes and sizes, including intricate designs and complex geometries.

5. Antibacterial Properties: Copper possesses natural antibacterial properties, suitable for applications in healthcare settings, food processing, and other industries where microbial growth must be minimized.

Regarding this copper steel copper cladded coil, KLS can usually provide widths of 230 millimeters, 340 millimeters, 540 millimeters, etc. As a professional copper sheet coil supplier, we also have the ability to customize reasonable widths within our production range according to the actual requirements of customers. We can always find a way to suit your needs.

Products have been exported to India, Russia, Europe, the United States, the Middle East, Saudi Arabia, Qatar, etc. Choose from a range of grades, lengths, and custom cuts to suit your project needs.

Specifications

| Product name | Copper clad steel coil |

| First layer material | C1020R |

| Secondl layer material | Stainless steel 316L |

| Third layer material | C1020R |

| Ball coil | Φ 500 |

| Die | No die |

| Tolerance for copper C1020R | 0.05mm ± 0.008mm |

| Tolerance for stainless steel 316L | 0.35 ± 0.05mm |

| Packaging | Wooden case |

Uses

Copper clad steel coil has a wide range of applications in various industries such as telecommunications, power transmission, automotive, and electronics. It is used in the manufacturing of wires, cables, connectors, and other components that require excellent conductivity and high strength.

Applications of Copper Sheet Coils:

1. Electrical Industry: Power transmission and distribution, electrical wiring, busbars, transformers, motors, and generators due to their exceptional electrical conductivity.

2. Heat Exchangers and Cooling Systems: Copper's excellent thermal conductivity makes it an ideal material for heat exchangers, radiators, air conditioning systems, and other cooling applications where efficient heat transfer is essential.

3. Architecture and Construction: Copper sheet coils are used in roofing, gutters, flashing, cladding, and decorative elements due to their corrosion resistance, longevity, and aesthetic appeal.

4. Electronics and Telecommunications: Copper is widely employed in printed circuit boards (PCBs), connectors, switches, and other electronic components due to its excellent conductivity and reliability.

5. Automotive Industry: Copper copper clad stainless steel coils find applications in automotive radiators, heat exchangers, wiring harnesses, and connectors, where their thermal and electrical properties are advantageous.

6. Industrial Equipment and Machinery: Copper is used in various industrial equipment, including pumps, valves, heat sinks, and industrial machinery components, to benefit from its excellent conductivity and corrosion resistance.

7. Medical and Healthcare: Copper's antimicrobial properties make it suitable for medical applications such as hospital equipment, touch surfaces, antimicrobial coatings, and antimicrobial textiles.

8. Arts and Crafts: Copper sheet coils are utilized in artistic and decorative applications, including sculptures, jewelry, ornaments, and architectural accents, due to their malleability and aesthetic appeal.