Copper-steel composite plate is steel as the grass-roots level, copper as a compound layer. It uses the explosion composite and rolled composite production of the total thickness of 8 ~ 10mm copper-steel bimetallic plate, steel base to meet the structure of strength, stiffness, toughness and weldability requirements, copper layer to meet the structure of corrosion resistance and other special properties of the requirements. Copper-steel composite plate saves a large amount of copper, reducing the structure manufacturing costs, and is suitable for chemical, petroleum, pharmaceutical and other fields.

Copper - steel composite steel plate commonly used deoxidized copper into oxygen-free copper for the compound layer, steel and copper at high temperature lattice type, lattice constant and atomic radius are very close, which is beneficial to welding. However, the melting point of copper and steel, thermal conductivity, linear expansion coefficient and other physical differences, causing certain difficulties to welding.

① copper steel composite plate of the compound layer and the grass-roots metal thermophysical properties are very different, copper and steel thermal conductivity and linear expansion coefficient difference is large, and copper-iron binary alloy crystallization temperature range is very large, so the weld is prone to thermal cracking and not weld through.

② compound layer is easy to oxidation formation of low melting point eutectic distribution at the grain boundaries, so that the weld plasticity is reduced, resulting in cracking.

③ grass-roots dilution of the transition layer weld, not only to reduce the conductivity of the compound layer, but also easy to make the weld pores and cracks and other defects.

④ copper to iron surface activity is high, liquid copper or copper alloy is likely to its contact with the near seam area of the steel surface internal penetration, so that the near seam area of steel to form penetration cracks.

In fact, the weld metal containing Ni, Al, Si copper alloys have less penetration into the steel, while the bronze containing Sn has serious penetration. In addition, the steel tissue state also has an important impact on the penetration crack, liquid copper can infiltrate the austenite and not infiltrate the ferrite, so the base for single-phase austenitic steel easy to produce penetration cracks, while the base for austenitic-ferritic dual-phase steel is not easy to produce penetration cracks.

Copper steel composite plate welding more suitable method is inert gas shielded welding (TlG, MG). When the copper compound thickness greater than 3mm, the recommended preheating temperature of not less than 150 ℃, with a diameter of less than 1.6mm copper welding rod, when the compound layer is thin, if the use of preheating, should first remove part of the transition layer and then weld the compound layer, in order to control the compound weld due to dilution of the iron content, to ensure its corrosion resistance.

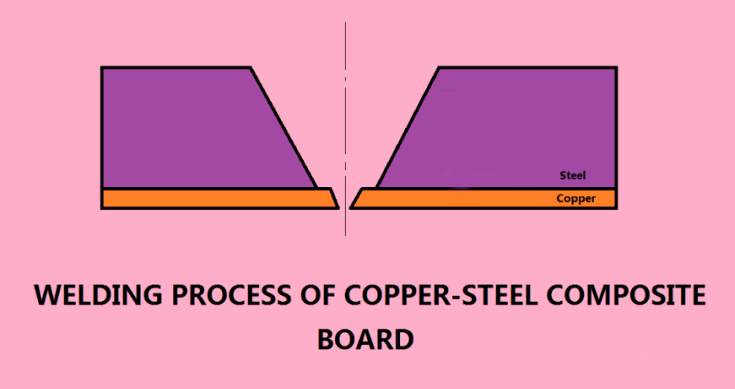

Bevel form can have a variety of, can first weld compound layer or first grass-roots welding, steel grass-roots welding to clear the root, made of transition layer and compound layer of the big early joint slope, and finally polished clean with a hand wheel.

Welding materials, the principle of the selection of the compound layer wire is to ensure that the weld metal has good electrical conductivity, crack resistance, mechanical properties and welding process performance. Transition layer wire selection principle is to be able to have good metallurgical compatibility with both copper and steel. As Ni and Cu, Ni and Fe in the solid state and liquid state can be infinite solid solution, the formation of a continuous solid solution, so nickel and nickel-based alloys are better transition layer wire materials.

When the thickness of the composite layer is less than 2mm, a layer of copper should be carefully deposited on the steel base layer, and then welded by semi-automatic MIG welding with backward tilting method, the arc acts directly on the molten pool and not on the steel base layer, so that the iron content of the first layer of the welding channel is less than 5% to prevent thermal cracking and penetration cracking. To prevent porosity, cracking and other defects and improve the cold bending resistance of the weld, in addition to the use of argon protection, but also the choice of heat concentration of welding methods, for example, the use of volume fraction of 75% He + 25% Ar helium-argon gas shielded welding.