Laminates are produced by bonding two or more metals together to form a single steel plate or plates. Stainless steel-carbon steel composite plate combines stainless steel and carbon steel materials through an explosion and rolling process, making the metal plate more resistant to corrosion, wear and high temperature and pressure. But welders will face a new problem is welding, and we all know that the welding of two different materials will be more complex and difficult.

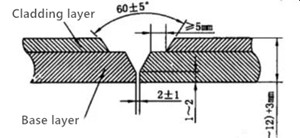

Generally speaking, the welding order of stainless steel composite steel plate is generally: first weld the inside of the base layer, then weld the back to the root after the outside of the base layer, and finally weld the transition layer and composite layer. (Notch diagram). However, the welding of the longitudinal ring weld of the small diameter cylinder (below 500 diameter) should be selected with an external bevel. Therefore, today we will learn the welding process of small diameter stainless steel composite plate pressure vessel.

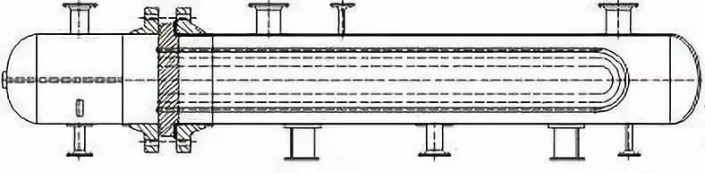

Hydrogen sulfide tower bottom reboiler (or U-tube heat exchanger). The medium contains ammonia, the vessel is made of Q245R + S31603 stainless steel composite plate, design pressure 1.18MPa, design temperature 189℃, diameter Φ600mm.

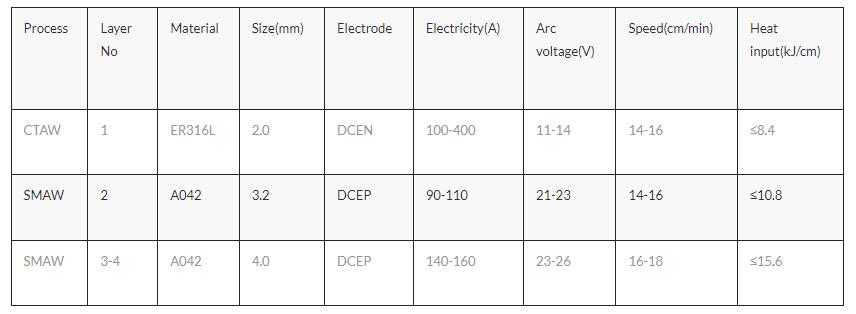

Due to the small diameter of the shell, it can only be welded from the outside, so the outer bevel - single-sided welding method is used. This bevel is welded by GTAW+SMAW on the outside of the barrel, and the welding sequence is: overlay welding, transition welding, bottom welding. Unlike the previous welding sequence, this welding sequence brings the choice of welding materials.

Considering the dilution effect of the base material, a welding material with high chromium-nickel content should be selected. The welding material for the base layer is generally stainless steel, and the overlay layer is generally ER316L (H03Cr19Ni12Mo2Si) wire, and then the transition layer and base layer are welded with electrode A042 (e309mol-16).

After passing nondestructive testing, the samples were tested for mechanical properties and intergranular corrosion. From the test results, it can be seen that the tensile strength, bending properties, impact properties and intergranular corrosion of the welded joints meet the standard requirements, proving that the welding process and welding materials w.

The experiment shows that the stainless steel composite plate can be welded in the following order: composite weld - welded transition weld - base weld. After cladding, the weld material of the base should be stainless steel. Using the GTAW + SMAW process, the stainless steel cladding plate of the small diameter cylinder is welded on the outside with the correct welding material, which can fully meet the standard requirements.