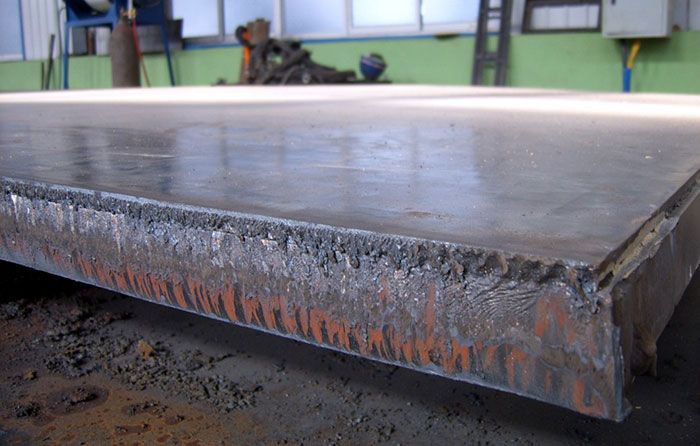

This is how the explosion-bonded clad plates are made. When the explosive is detonated, the energy generated by the explosion makes the cladding material hit the base material at a very high speed. Meanwhile, the high temperature and high pressure prompts these two materials to be fused together and never ever separate from each other again.

Overview

Explosion bonded clad plate is a composite material composed of two or more different metal layers. They are bonded together by the process of explosive bonding. Compared with the traditional cladding method, explosive adhesion provides excellent bonding strength and corrosion resistance, as well as improved mechanical and thermal performance.

Features

Explosion bonded clad plates feature a super high bonding strength. The shear strength can be able to reach 400MPA or above. Explosion bonding technology can produce a clad plate that uses a low alloy steel as a base metal and a non ferrous metal as a cladding metal. Meanwhile, explosion bonding technology can produce a clad plate with a total thickness up to 200mm. Specifications and plate types can be customized according to client needs. What's more. Clad plates of round shape can only be produced by explosion bonding.

Specifications

| Type | Clad steel plate (explosion bonding) |

| Thickness | Total thickness:12-200mm (cladding material thickness:2-15mm) |

| Plate type | Specifications and plate types can be customized according to client needs |

| Shape | Round shape can be produced by explosion bonding |

| Finish | No.1 or as per your requirement |

| Standard | NB/T 47002.1—2009, For Russia Market |

| Materials | Base materials:carbon steel (Q235B, Q245R, Q345R) and 16Mn, Cladding materials:stainless steel 300 series, duplex 2205 and titanium, etc |

| Application | Petroleum, chemistry, electricity, paper making, alkali making, irrigation works, automobiles, salt, medicine, food and public facilities |

| Package | Standard export sea-worthy package |

| Delivery Time | Usually 15-25 days after receiving the 30% deposit |

| Payment terms | TT, L/C, DP or Negotiable |

| Container Size | 20ft GP:5898mm(Length)x2352mm(Width)x2393mm(High)40ft GP:12032mm(Length)x2352mm(Width)x2393mm(High)40ft HC:12032mm(Length)x2352mm(Width)x2698mm(High) |

| Note | We are so able to produce other standard as per the clients' requirements, Just let us know |

Uses

Applications of explosion bonded clad plates:

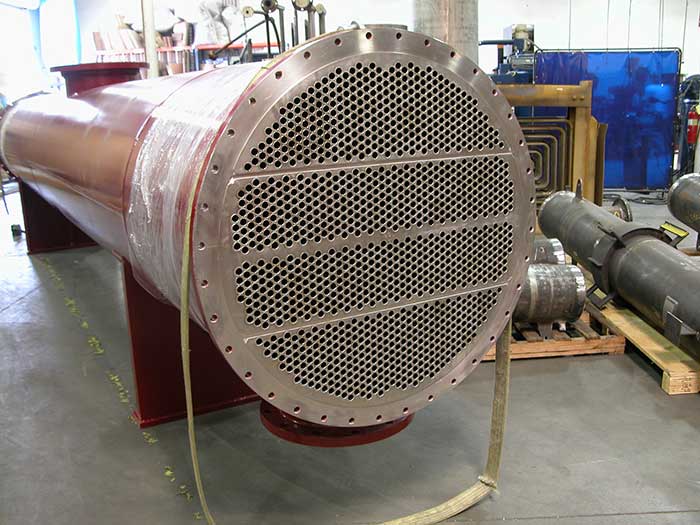

1. Chemical processing: Equipment exposed to harsh chemicals, such as reactor vessels, piping, and heat exchangers.

2. Power generation: Boilers, turbines, and heat exchangers in power plants due to its high resistance to corrosion and high temperature.

3. Marine and offshore: Shipbuilding, oil rigs, and other marine structures for corrosion resistance and improved durability in harsh environments.

4. Aerospace: Aircraft components, such as engine parts, for its high strength and durability.

5. Nuclear: Nuclear reactors and fuel storage containers for its high resistance to radiation and ability to withstand harsh conditions.

If you are looking for wholesale explosion bonded clad plates with factory supply price or metal cladding solutions with custom service, welcome to contact us for more information!